Be careful of the spinning propeller if you happen to shift or start the engine while you are setting up. Zero out the gauge after testing each cylinder.

Checked it out long enough to do the compression test then bought it.

How to do a compression check on an outboard motor. There are two basic ways to compression test an outboard. The first is called a leak down test. This uses a special set of gauges.

To perform a leak down test you would pressurize the cylinder with compressed air. One gauge will tell you the pressure of the air compressing the cylinder. The second gauge will show you how much pressure has been lost.

How to Compression Test an Outboard Motor BoatUS - YouTube. Knowing how to perform a compression test is essential if you are buying or maintaining any outboard motor. This is the process.

Screw the end of the compression gauge into one cylinder. Go to the key and turn the engine over for 3 to 5 seconds. It doesnt matter whether you turn it over for 3 or 5 seconds.

What matters is that you turn it over for a consistent time on each of the cylinders. HOW TO DO A OUTBOARD COMPRESSION TEST - YouTube. How to perform a basic compression test on any outboard motor also a description of tools needed.

How to perform a. A compression check can tell a lot about the health of your outboard engine. Heres why and how its done.

Four Stroke Engine Illustration There are four distinct phases in a four-stroke cycle. Induction compression power and exhaust. A lot can be learned by checking the engines ability to compress the gasair mixture.

How to - outboard compression check Probably best to post this in the outboard repair forum for your engine make. - Get a engine compression tester - Test can be performed out of the water on the hose - Warm up the engine - remove the spark plugs - screw compression tester into one of the cylinders - crank the engine a few cranks. How Do You Do A Compression Test On An Outboard Motor.

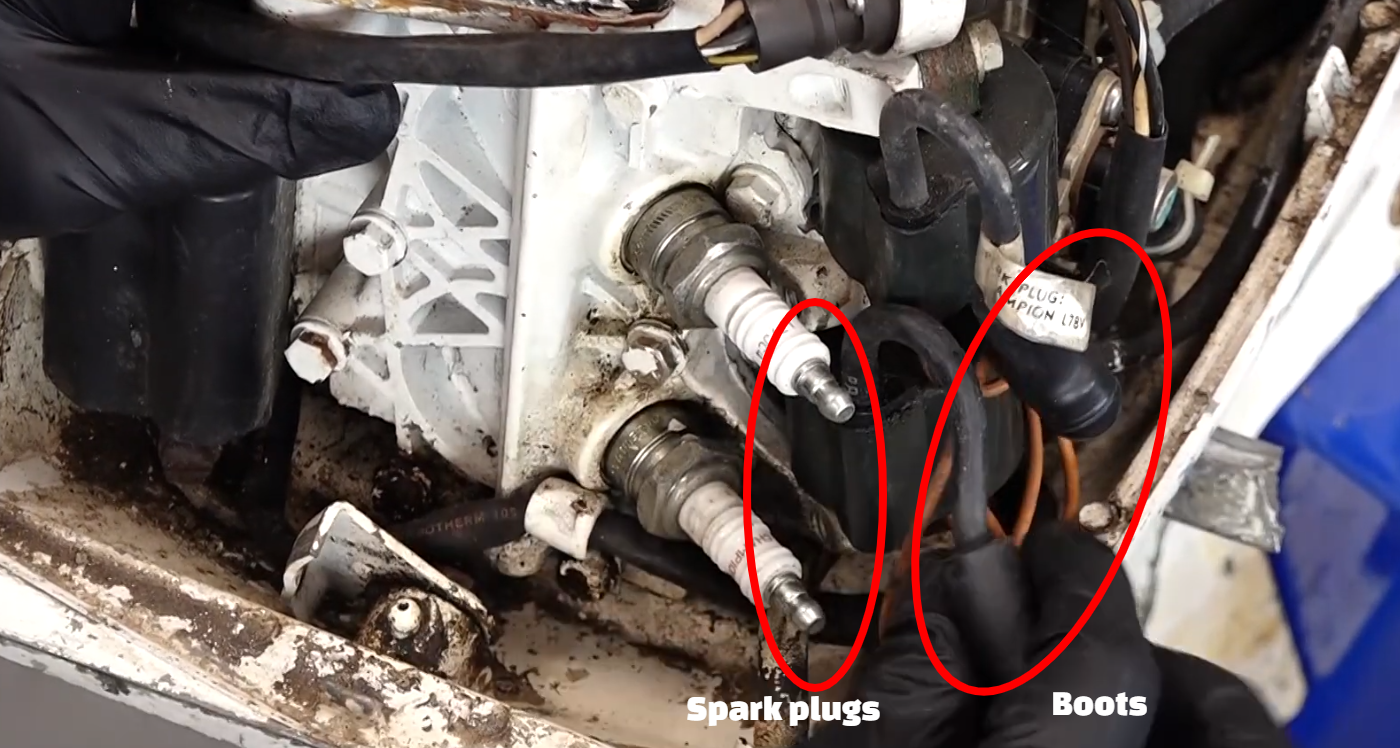

Performing the compression test is actually a pretty simple process. You are going to want to take off any of those covers that we talked about earlier from over the top of the ignition coils. Once you are looking at your engine and you get the ignition coils exposed.

To perform the test crank the engine 4 times by turning the key in your cars ignition then check the compression gauge for the result. After you get a result for the first cylinder repeat the process for all of the other cylinders. If in doubt about your readings talk with your dealer to see if theyre in the ballpark.

Generally readings below 90 PSI for modern two-stroke outboards indicate a problem. Most will produce cranking compression readings in the 90 to 105 PSI range depending on. Older two cycle outboards especially low horsepower can run fine around 60 psi however above 90 psi is optimal.

Four strokecycle engines produce much higher compression. The main thing to check is the difference between cylinder compression. Cylinder-to-cylinder compression readings that differ more than 10 reveal trouble.

Outboard Engine Compression Check. The compression check is probably one of the first things you would want to check before you purchase a used outboard motor. The procedure may seem daunting to a beginner but is fairly quite simple and it is crucial that an engine have good compression before you purchase.

Below is a 6 step process on how to test outboard motor compression. Be careful of the spinning propeller if you happen to shift or start the engine while you are setting up. The engine should not fire and you can achieve this by pulling on the switch that kills the engine.

Crank over the motor the same amount of times for each cylinder during testing. Zero out the gauge after testing each cylinder. If your motor is equipped with an electric start option count the number of second.

On manual or pull start motors pull the starter rope 4 or 5 times for every cylinder you test. Write down the data from each cylinder. Step number one when checking the compression in your motor is to be cautious of the spinning propeller on your boat.

You need anything possible to make sure that the ignition doesnt fire because the propeller is going to start up and be extremely dangerous if you start the engine up. You should do a spark and compression on the engine. Then you should check over the boat.

Look at these main points. The fuel tank the hull the stringers and the transom. You want to make sure that all of these check out and are in good.

Set the throttle wide open and then pull the pull cord six or seven times to test the compression. Next check the gauge on the compression tester. Johnsons specs are for the engines compression to be between 85 and 90 PSI so this cylinder passes.

Compression check cold vs hot. I was a terrible buyer on this one. When I stopped to look at it the other day I was in a big hurry.

Basically could look at it long enough to hear it start up and run. Then same story when I bought it. Checked it out long enough to do the compression test then bought it.

Its actually a 75 Evinrude 70HP. On two stroke a compression test is quick easy and painless. On a 4 stroke it is a teat on a boar hog.

I cannot tell you how many 4 strokes have passed a compression test with leaking headsleaking valves and stuck rings due to carbon. Yet the compression was good and the leakage rate above 70. But dont go running out to buy a compression test kit quite yettheres more to an outboard motor than compression and theres an easier way to diagnose the overall condition of a motor now that were in the 21st century.

Most outboard motors and inboards and diesels too are electronic and have been since the 1990s.