There are different connections depending you power the motor with 120V or 240V. The contacts can also arch and get a tit on them that prevents good contact.

If the capacitor has failed the symptom is that the motor wont start.

Electric motor won t start. When an electric motor wont start and we have confirmed that power is being delivered usually we suspect that the motor windings or the start switch have failed1 Be sure youve checked for thermal overload first. Normal electric motor winding resistance. At BASIC ELECTRICAL TESTS for BURNED OUT COMPRESSOR MOTORS.

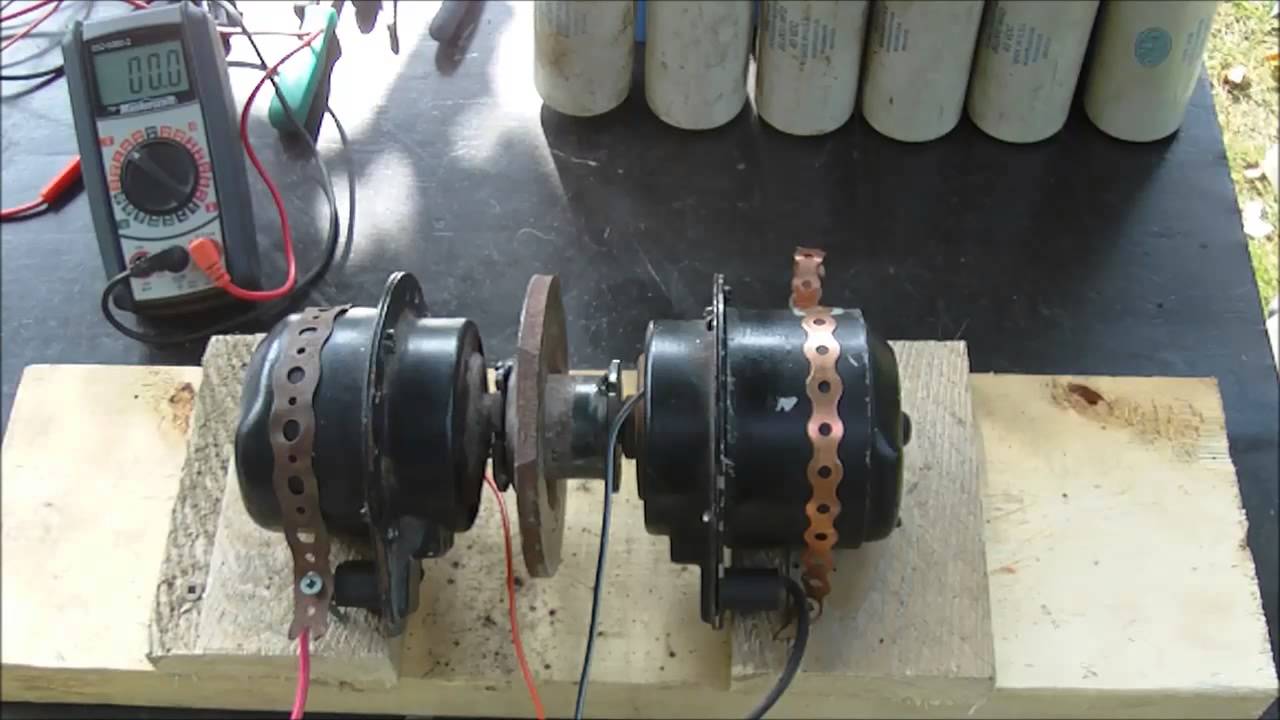

Diagnostic Checks You Can Make When an Electric Motor Will Not Start. A start capacitor can go bad even start to go bad and get weak. Capacitors are like a battery and hold quite a charge so be careful.

Turn off the power to the compressor. What to do if your electric motor wont start. Electric motors or equipment may also be taken into an electric motor repair shop for extensive diagnosis and servicing.

Testing the motor and capacitor should only be made after the electric motor circuit has been identified and turned OFF and Tagged. If the capacitor has failed the symptom is that the motor wont start. You may hear it humming or observe that its getting hot.

If you observe this we suggest that to avoid damage you turn off the system while waiting for repairs. In an older motor fully assembled the switchs contacts may have become pitted and burned or its parts may be worn so that there is not enough pressure to close the contacts when the motor is not running or is first starting up. Look closely at your motor and find.

Run winding seldom or Run capacitor very few motors fitted with it - Symptoms. Motor wont start or alternatively will not have power if it manages to run. Centrifugal switch if fitted - Symptoms.

Motor will start and run well might have a slight very high pitch noise and will draw more current waste electricity than what it was designed for. If your motor has a capacitor it is not a split phase motor. Split phase motors have very poor starting torque so you wont find them on tools of any size.

They do however have centrifugal switches that can fail. Dirt can get in between the contacts like said. The contacts can also arch and get a tit on them that prevents good contact.

With proper capacitors the motor should start even under the load. If the capacitors are the problem and the motor is not able to start with no load this mean the capacitors should be dead completely. According to your measurements the capacitors are not dead.

There are different connections depending you power the motor with 120V or 240V. Electric Motor Starting Problems When the motor sits and hums instead of starting the problem could be in a switch or in the starting capacitor. Question When I try to start my Delta X5 230v 3hp Unisaw GPE switch I get a strong hum and the blade turns slightly.

Is there a starter that can be tested and or replaced. If theres a belt you could remove it and check the turntable rotation and motor rotation separately also can check if the motor starts with no well less load or not. Also you could very slowly rotate the motor and see if it starts - if this does it there could be a dead zone on the servo or brush inside the motor and maybe a new one would fix it.

The start windings are probably what you hear humming. The older motors had a red reset button on the non-drive end bell that you had to manually reset. Now they reset automatic at the cooled down temp.

All of this is assuming that if you let the motor cool. Electric Motor Starting Issues - YouTube. I am performing service on vent motors replacing belts.

After I replaced the belt on this unit it wouldnt start yet was making a noise. I suspect that the unloader valve is stuck in the closed position forcing the compressor to start against pressure something it wont be able to do. Its easy to check for though open the tank vent and and remove anything attached to the pressure port and see if it starts and runs and air comes out.

If not then there may be a faulty compressor an obstruction in the airline or a faulty controller. Check the windings for short circuiting to the frame. Most household appliance motors with a shorted winding will not run and will probably open the fuse or trip the circuit breaker instantly 600 volt systems are ungrounded so a 600 volt motor with a shorted winding may run and not trip a.

Since a single phase motor has a start winding a run winding the motor can be reversed by reversing the start windings. This has nothing to do with the capacitor since it is only used to temporarily sync the start run windings together. Once the motor is at 60-70 of rated speed a centrifugal switch disconnects the start winding.

DC Motor wont start up. Reply 11 on. February 11 2014 040536 am.

If you dont have power supply that will give 10A or about you might try to spin the motor by hand while connecting to 4A power supply. As mentioned above starting current is way too high for your power supply to start it. Check the pressure witch if the air compressor motor wont start.

Unplug the compressor from the electrical outlet and bleed air from the tank. To carry out this process open the drain valve and release the air. Attaching a blowgun to the drain valve can empty water vapor and air from your compressor tank properly.

Electric Motor turns slow under or will not start under load Electric Motor turns slow under or will not start under load Nurples Military OP 15 Sep 09 1153. Hello Im currently deployed to Iraq with the US Army and Im working on hooking up an air compressor. I am not an.

If the compressor wont start with air in tank replace the check valve. If the compressor wont start with an empty air tank replace the pressure switch if it isnt activating the pump motor. Replace the pump motor if it doesnt start when activated by the pressure switch.

STARTING TROUBLES Trouble 2. Motor wont start No hum or heating Page 6 Trouble 3. Motor wont start Just hums and heats up Page 6 Trouble 4.

Overload relays trip during starting Page 6 Trouble 5. Motor starts but comes up to speed slowly Page 7.